This application focuses on measuring inorganic metals including: copper (Cu), zinc (Zn), arsenic (As), selenium (Se), cadmium (Cd), and antimony (Sb), using Cooper Environmental’s Xact® 920, a continuous multi-metal monitor based-on energy dispersive X-ray fluorescence.

Industrial facilities consume and discharge various chemicals as a byproduct of the commodity they produce. The discharge from these large facilities must meet local and national agency pollution requirements. To meet these requirements and minimize environmental impacts, facilities use wastewater treatment plants (WWTP) coupled with continuous monitoring.

Continuous monitoring can be demonstrated by monitoring inputs and operational parameters (i.e. pH, ORP, flow rate and flocculant dose rates), surrogates (i.e. TDS, TSS and turbidity) or by monitoring the actual pollutant of interest. Continuous monitoring for the actual pollutant of interest is the preferred method but can be cost and time prohibitive. Monitoring the actual pollutant of interest mitigates issues with poorly correlated surrogates, and upset events not observed from operational parameters.

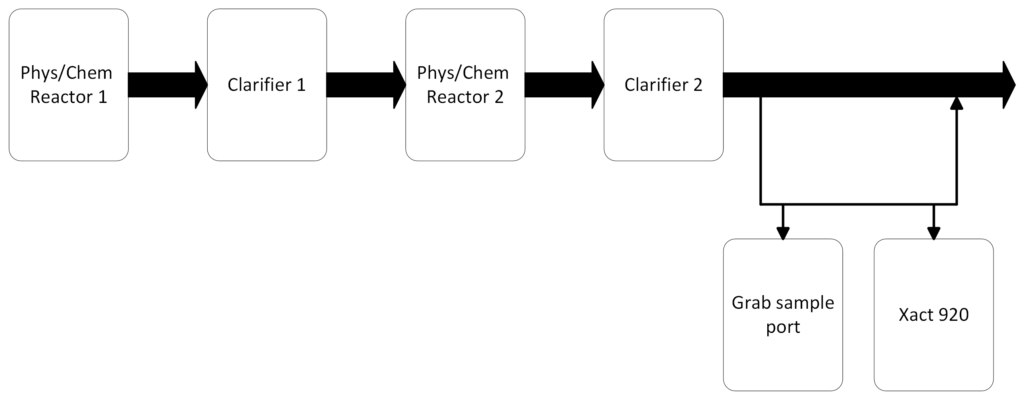

The Xact® 920 was installed downstream of an effluent treatment plant (ETP) clarifier, at one of the world’s largest smelting facilities which produces various metals and chemicals. The ETP treats effluents from different plant processes in addition to run-off by rain, snowmelt, and water spray to reduce fugitive road dust emissions. The ETP uses lime (CaO), a flocculent, and clarifier tanks to remove metals and other pollutants before discharging. Figure 1 shows the Xact® 920’s sample location relative to the ETP treatment process.

Data presented in this paper was collected over an eight-month demonstration in 2016. The Xact® 920 collected samples in a continuous online configuration providing total metals concentrations every 30-minutes. Periodic grab samples were collected and analyzed by the Xact® 920 and laboratory inductively coupled plasma mass spectrometry (ICP-MS) using modified US EPA 200.8 methodology. The Xact® 920’s performance was evaluated for sample matrix effects (matrix spike recovery) and overall comparison to laboratory ICP-MS results.

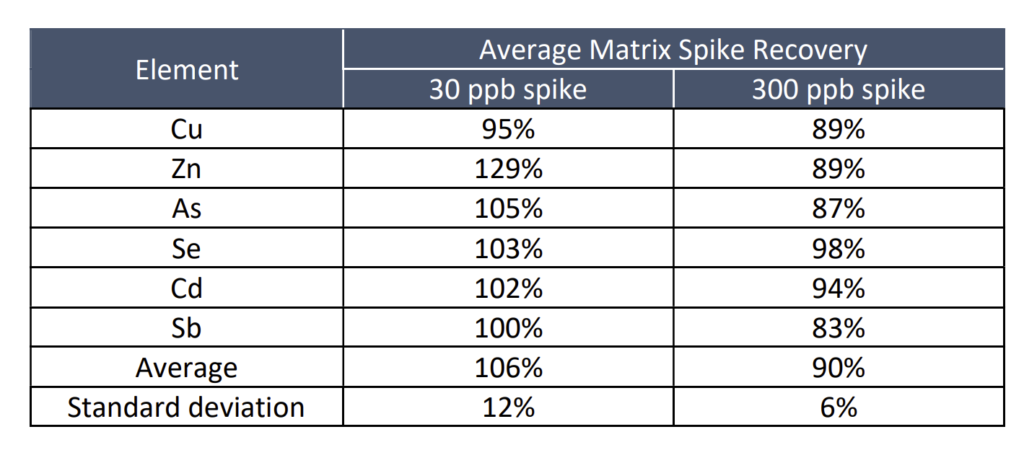

The Xact® 920’s analysis was evaluated for sample matrix effects using matrix spike recovery analysis. Spike recovery was performed twice on the ETP effluent sample at nominal spike concentrations of 30 and 300 ppb. Table 1 summarizes these results for Cu, Zn, As, Se, Cd and Sb. The overall average spike recovery for all six metals was 99.1% ± 12.0%. This demonstrates little to no matrix effects on the Xact® 920’s analysis. For reference the U.S. EPA recommends a spike recovery range of 70% to 130%.

Table 1: Xact® 920 matrix spike recovery for ETP effluent

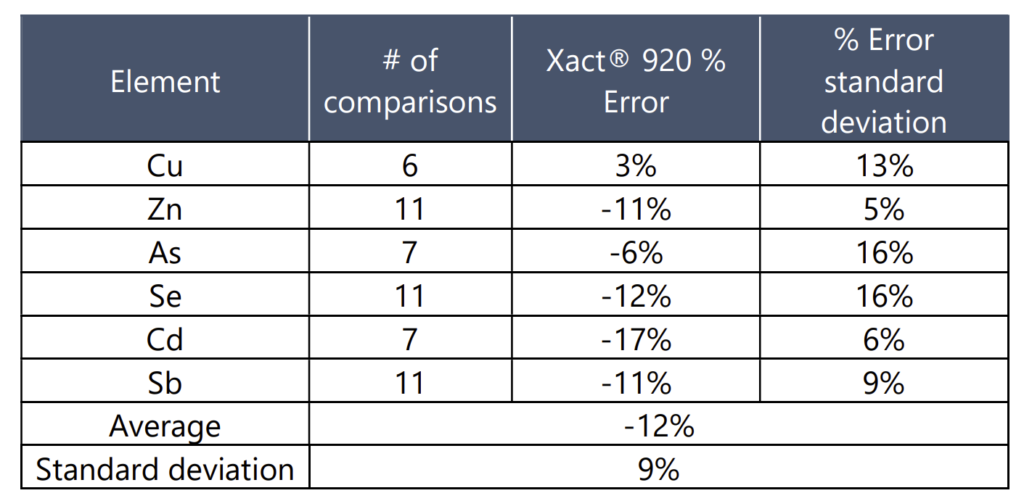

The Xact® 920 was also compared to laboratory ICP-MS for Cu, Zn, As, Se, Cd, and Sb in the ETP effluent sample. The overall average percent error relative to ICP-MS was -12.1% ± 8.8%. Table 2 summarizes the percent error analysis for this study.

Table 2: Xact® 920 percent error analysis relative to ICP-MS

This application demonstrates the Xact® 920 can provide accurate, continuous, near real-time measurements for Cu, Zn, As, Se, Cd and Sb in industrial wastewater. Mitigating uncertainties when monitoring inorganic pollutants using operational parameters or surrogates for compliance or process monitoring.

For more information about the Xact 920 technology, please contact Cooper Environmental at info@sci-monitoring.com.

Comments are closed